ChrisB

Elite Cafe Member

Hi All,

Having to take it easy and also banned from the Knife workshop by the BOSS!!

For A while ? (Due to a recent Heart Attack)

I was Messing around with some drawings and new logo's for my Knives, then it Struck Me!!

I recently Bought a "Etch-o-Matic" etching system with the stencil Maker from Martronics in the USA.

The Old Method of Clear stencils Pheric Cloride and Positive-20 takes to much time and Hassles.

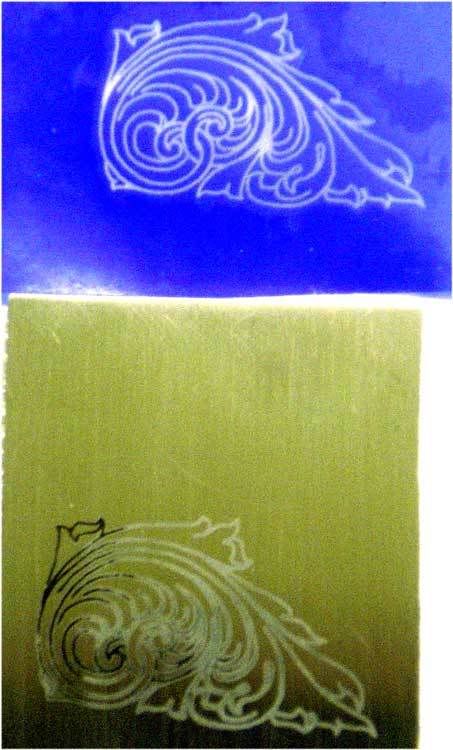

Why not make a stencil for one of my engravings for the hunters and try it.?

I did one and it works like a dream,

It's a Fine Silkscreen Media that You develop your image onto, then you just put in in place, use the Etching block and it makes a perfect fineline marking on the steel, I tried it on a variety of st/st that i use in my knifemaking and it marks them all. in minutes.

They Also Say that it will mark any conductive metal,!! I will try it out this weekend on Brass,Copper,Nickle Silver, Aluminium Etc. And post reply.

You can even use the same stencil and just turn it around for a mirror image !!

It lines up Perfectly the same as a Clear Transparency.

And You can use it over and over, Perfect for repetitive jobs !! also at a fraction the price of a Epson Sheet. That You can only use once.!!

It Only takes about 5 min. to produce a stencil !!

They Also supplied a Glass etching Sample, which I Marked a beer glass for my son, with his Racing logo on it

curved both ways, it came out Great.!!!

The Unit sold for $200.

Having to take it easy and also banned from the Knife workshop by the BOSS!!

For A while ? (Due to a recent Heart Attack)

I was Messing around with some drawings and new logo's for my Knives, then it Struck Me!!

I recently Bought a "Etch-o-Matic" etching system with the stencil Maker from Martronics in the USA.

The Old Method of Clear stencils Pheric Cloride and Positive-20 takes to much time and Hassles.

Why not make a stencil for one of my engravings for the hunters and try it.?

I did one and it works like a dream,

It's a Fine Silkscreen Media that You develop your image onto, then you just put in in place, use the Etching block and it makes a perfect fineline marking on the steel, I tried it on a variety of st/st that i use in my knifemaking and it marks them all. in minutes.

They Also Say that it will mark any conductive metal,!! I will try it out this weekend on Brass,Copper,Nickle Silver, Aluminium Etc. And post reply.

You can even use the same stencil and just turn it around for a mirror image !!

It lines up Perfectly the same as a Clear Transparency.

And You can use it over and over, Perfect for repetitive jobs !! also at a fraction the price of a Epson Sheet. That You can only use once.!!

It Only takes about 5 min. to produce a stencil !!

They Also supplied a Glass etching Sample, which I Marked a beer glass for my son, with his Racing logo on it

curved both ways, it came out Great.!!!

The Unit sold for $200.