Lonestarr

Elite Cafe Member

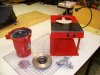

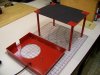

Hi Folks I would like to share with you some equipment that I have built for my engraving hobby. Part one will be my power hone, a simple but effective piece of equipment. It was designed with an open type architecture which uses a 110 volt 1750 rpm 1/2 hp motor with a cast iron flywheel. So far, after about two months use it has become a favorite tool. For bit honing it uses the Lindsey template system. The flywheel height from the deck is set by shim packs under the motor mounting bolts, a bit of a hassle but not bad. I added a brake lever on the right of the flywheel, stops the rundown of the flywheel to 2 seconds.

Pros of the build

*very smooth and quiet

*simple design and easy to build

*lots of power

Cons

*very heavy clocks in at 51 lbs

* deck height setting not convenient

Hope you like the hone...Bob

Pros of the build

*very smooth and quiet

*simple design and easy to build

*lots of power

Cons

*very heavy clocks in at 51 lbs

* deck height setting not convenient

Hope you like the hone...Bob