The attached pictures show ring holder modifications that I made to make positioning rings for engraving quicker and more precise.

The first modification grew out of a recent post on a vertical ring holder (Thanks jimzim75!) and some of the comments that were made concerning the need to keep the ring close to the top of the vise. The thought is to have a very simple, stable holder for the ring. I took the screw, machined steel cone, and the plastic sleeves from the GRS Horizontal Positioning Ring Holder (#004-847) and attached it directly to the vise jaw. It gives me a very solid support for the ring.

The vise jaw is drilled with a 3/16" drill to a depth of about 1.5 inches. The hole is reamed out with a 13/64" drill, the rough edge removed with a lightly applied countersink, and tapped with a 1/4-20 tap to the full depth of the hole. I went back with a plug tap to get threads the full depth of the hole, but you may elect not to do that depending on the length of the flat-head cap screw used to hold and expand the plastic ring holder.

Be sure to get all the chips from the drilling and tapping operations out of the hole before you try to use the holder!!

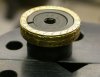

The first picture shows the tapped hole in the vise jaw with the parts from the ring holder. The second picture shows the ring holder in action. I believe that you can get the flat head cap screw and machined cone as replacement parts from GRS.

The second modification was the use of a Lee Valley eccentric clamping lever and a 1/4-20 cap screw with the GRS #004-679 Inside Ring Holder. I have been using this mod for about 2 years and like the ability to flip the lever up, reposition the ring and clamp it again without digging out the Allen wrench to make the adjustment. I used to roll the vise to keep from repositioning, now with a quick flip of the lever, I can stay in the sweet spot under the microscope and keep moving around the ring.

My ring holder has a 5/16" screw which allowed me to use a 1-1/4 inch long 1/4-20 socket head cap screw without modifying the holder. I needed an additional washer to make the clamp work without the screw extending through the clamp nut and binding on the lever. The third picture shows the setup.

Use an Allen wrench to set the initial tension and the lever to snug it up.

The clamping lever is available from Lee Valley:

http://www.leevalley.com/hardware/page.aspx?c=2&p=45034&cat=3,43576,52799

The first modification grew out of a recent post on a vertical ring holder (Thanks jimzim75!) and some of the comments that were made concerning the need to keep the ring close to the top of the vise. The thought is to have a very simple, stable holder for the ring. I took the screw, machined steel cone, and the plastic sleeves from the GRS Horizontal Positioning Ring Holder (#004-847) and attached it directly to the vise jaw. It gives me a very solid support for the ring.

The vise jaw is drilled with a 3/16" drill to a depth of about 1.5 inches. The hole is reamed out with a 13/64" drill, the rough edge removed with a lightly applied countersink, and tapped with a 1/4-20 tap to the full depth of the hole. I went back with a plug tap to get threads the full depth of the hole, but you may elect not to do that depending on the length of the flat-head cap screw used to hold and expand the plastic ring holder.

Be sure to get all the chips from the drilling and tapping operations out of the hole before you try to use the holder!!

The first picture shows the tapped hole in the vise jaw with the parts from the ring holder. The second picture shows the ring holder in action. I believe that you can get the flat head cap screw and machined cone as replacement parts from GRS.

The second modification was the use of a Lee Valley eccentric clamping lever and a 1/4-20 cap screw with the GRS #004-679 Inside Ring Holder. I have been using this mod for about 2 years and like the ability to flip the lever up, reposition the ring and clamp it again without digging out the Allen wrench to make the adjustment. I used to roll the vise to keep from repositioning, now with a quick flip of the lever, I can stay in the sweet spot under the microscope and keep moving around the ring.

My ring holder has a 5/16" screw which allowed me to use a 1-1/4 inch long 1/4-20 socket head cap screw without modifying the holder. I needed an additional washer to make the clamp work without the screw extending through the clamp nut and binding on the lever. The third picture shows the setup.

Use an Allen wrench to set the initial tension and the lever to snug it up.

The clamping lever is available from Lee Valley:

http://www.leevalley.com/hardware/page.aspx?c=2&p=45034&cat=3,43576,52799