Barry Lee Hands

~ Elite 1000 Member ~

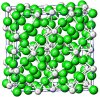

Notice this pic:

Tungsten carbide molecular crystal, three faces, 3 divided by 360 degrees equals 120 degrees.

Is it coincidence that we like 110- 120 degree carbide gravers?

I think it is just the fact the molecules like to stack that way. . .

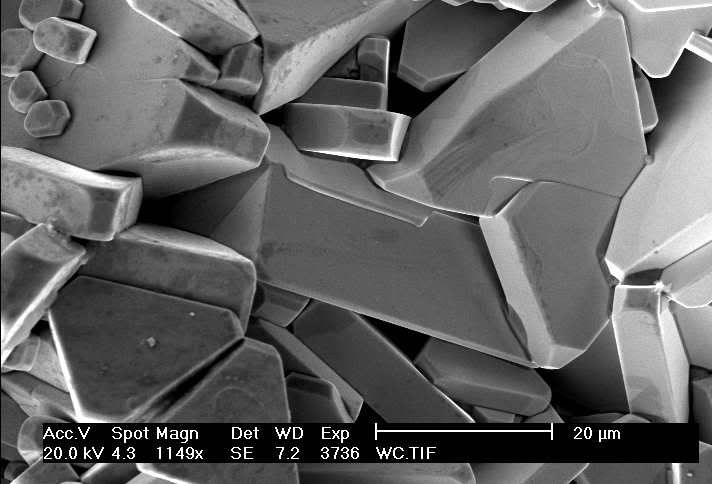

Here is an iron crystal, four faces, 360 divided by 4 equals 90 degrees, is it any wonder we sharpen our high speed steel gravers to 90 degrees with a 45 degree face?

Tungsten carbide molecular crystal, three faces, 3 divided by 360 degrees equals 120 degrees.

Is it coincidence that we like 110- 120 degree carbide gravers?

I think it is just the fact the molecules like to stack that way. . .

Here is an iron crystal, four faces, 360 divided by 4 equals 90 degrees, is it any wonder we sharpen our high speed steel gravers to 90 degrees with a 45 degree face?

Last edited: