jasincarlin112

Member

- Joined

- Dec 26, 2007

- Messages

- 22

Hey guys,

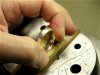

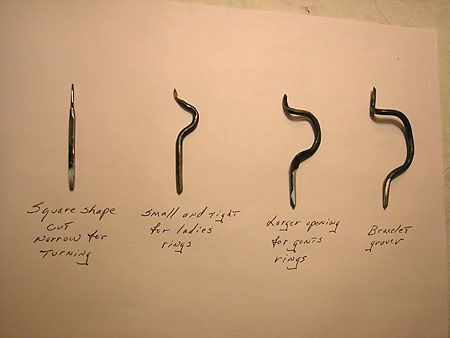

I'm having such a rediculously hard time trying to figure out how to go about engraving inside of wedding/engagement rings. In my shop, located inside of a jewelry exchange, its in really high demand. I've never attempted to try to engrave inside before, so i bought the three tools from GRS and the inside engraving holder. Would it be more beneficial to push engrave as opposed to using my GraverMach. Just seems like such a headache trying to figure it out myself. I apprieciate you guys taking the time to read this. Please help if you can.

I'm having such a rediculously hard time trying to figure out how to go about engraving inside of wedding/engagement rings. In my shop, located inside of a jewelry exchange, its in really high demand. I've never attempted to try to engrave inside before, so i bought the three tools from GRS and the inside engraving holder. Would it be more beneficial to push engrave as opposed to using my GraverMach. Just seems like such a headache trying to figure it out myself. I apprieciate you guys taking the time to read this. Please help if you can.