Billzach

Elite Cafe Member

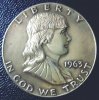

This is a frankin half dollar carving i finished today, look at the letters l & i on liberty and downward into the field., see the marks, pits, small humps, also look at the area around the word -we- on bottom of the coin, this coin has foreign material in it [ a coin carver,s worst night-mare ], it didn,t show until i had the coin 75% carved..i don,t know the percentage of coins that have foreign material in them, but over the last 11 years i,ve found maybe 20..if i find a coin with foreign material early in the carving of a coin, i,ll toss it into the junk bucket, but this one didn,t show until i started carving the hair, i was going to carve the hair with some flowers and such, but decided not to because of the foreign material...If you ever get one and catch it early in the carving process, junk it, if late in a carving try to make it work..