Bill Ellis

Member

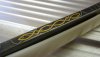

The etching will be done after heat treat/tempering and final sanding. Then it is dipped into ferric chloride for a bit and the pattern will show up again. The gold would not be affected... I don't think.Bill this is a question and not a comment. I have never done any work with damascus steel so I am asking this for education. It is my understanding that for damascus pattern to show up that the steel is givin a acid bath, is this correct? If so does this happen before or after heat treating the steel and will the acid have any effect on the inlay work?