Roger Bleile

~ Elite 1000 Member ~

Many of the experienced and highly skilled engravers here at the Cafe' started their careers as gun engravers. For that reason when we talk about ornamental design we focus on what I like to call "gun scroll." There are many styles of scroll used on guns as you will find illustrated at www.engravingglossary.com.

While gun scroll looks good on just about anything you can carve or engrave, there are somewhat different styles of ornament that can be used effectively on jewelry, knives, musical instruments, and watches.

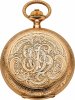

A good source of ideas can be found on the cases of 19th and early 20th century pocket watches. Watch case engravers of that era all engraved with the hand pushed burin. Much of the time the hand engraving was combined with background treatment done with a rose engine lathe. You will find that most of the watch case ornament is far more floral than gun scroll, which is mostly scrolling vines.

An excellent source of images of these watches can be found at Heritage Auctions. When you click on the thumbnail of the watch a full description along with additional images will come up. When you click on the additional image you will see a very large high resolution image that will allow you to actually see into the cuts of the engraving.

Here is a link to the current auction of post 1900 pocket watches: https://jewelry.ha.com/c/search-results.zx?No=0&Ne=2024&N=790+231+776+2050

There are literally hundreds of watches featured. Not all have engraved cases but if you open the ones with hunter style cases most will be engraved. You will also find that many have hand engraved inscriptions on the couvet inside the back cover or elaborate monograms on the back of the case.

One thing you will see frequently on American pocket watches is a sort of poor quality English scroll used as background or filler. In the watch trade this is known as "vermicelli." The vermicelli is one part of the design I would not replicate unless you replace it with good English scroll. The last watch in the group below has the vermicelli on the outer edges of the design.

Below is just a small sample of the kinds of engraving you will find on the watches. The images you can see at Heritage Auctions will be much larger than those on this forum.

While gun scroll looks good on just about anything you can carve or engrave, there are somewhat different styles of ornament that can be used effectively on jewelry, knives, musical instruments, and watches.

A good source of ideas can be found on the cases of 19th and early 20th century pocket watches. Watch case engravers of that era all engraved with the hand pushed burin. Much of the time the hand engraving was combined with background treatment done with a rose engine lathe. You will find that most of the watch case ornament is far more floral than gun scroll, which is mostly scrolling vines.

An excellent source of images of these watches can be found at Heritage Auctions. When you click on the thumbnail of the watch a full description along with additional images will come up. When you click on the additional image you will see a very large high resolution image that will allow you to actually see into the cuts of the engraving.

Here is a link to the current auction of post 1900 pocket watches: https://jewelry.ha.com/c/search-results.zx?No=0&Ne=2024&N=790+231+776+2050

There are literally hundreds of watches featured. Not all have engraved cases but if you open the ones with hunter style cases most will be engraved. You will also find that many have hand engraved inscriptions on the couvet inside the back cover or elaborate monograms on the back of the case.

One thing you will see frequently on American pocket watches is a sort of poor quality English scroll used as background or filler. In the watch trade this is known as "vermicelli." The vermicelli is one part of the design I would not replicate unless you replace it with good English scroll. The last watch in the group below has the vermicelli on the outer edges of the design.

Below is just a small sample of the kinds of engraving you will find on the watches. The images you can see at Heritage Auctions will be much larger than those on this forum.