You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Gold inlaying letters on a Colt SAA second generation Barrel, by Barry Lee Hands

- Thread starter Barry Lee Hands

- Start date

GTJC460

~ Elite 1000 Member ~

I use a square graver I convert to a micro flat by just grinding a very small flat at the tip. Is a very controllable tool that doesn't give much if any heel drag in the curvy bits.

Then I chisel the edges to make the undercut.

That's how I did the lettering on these barrels

Then I chisel the edges to make the undercut.

That's how I did the lettering on these barrels

Attachments

Barry, that looks super clean work. Thanks for showing how you do it.

That sounds interesting. Do have maybe a drawing or a photo of how the graver looks after you're "done" with it? I currently fail to quite imagine how it looks...

I use a square graver I convert to a micro flat by just grinding a very small flat at the tip. Is a very controllable tool that doesn't give much if any heel drag in the curvy bits.

Then I chisel the edges to make the undercut.

That's how I did the lettering on these barrels

That sounds interesting. Do have maybe a drawing or a photo of how the graver looks after you're "done" with it? I currently fail to quite imagine how it looks...

Boomhower

Elite Cafe Member

Thanks for the tips. I have a few guns I wood love to do this to. I just have to get where I can trust my self lol

GTJC460

~ Elite 1000 Member ~

It's not an original idea. This graver shape is more traditionally known as a scorper. It's discussed in Art of Engraving by Meeks on page 35. He uses an onglette to illustrate the scorper but really any point graver could be used. I just have more "square" gravers laying on my bench so that's typically what I modify.

Attachments

GTJC460

~ Elite 1000 Member ~

One thing all engravers will find when inlaying rollmarks is that most are not uniformly deep. Typically one side of the lettering isn't as deep as the other, which is why you need to recut the marks. its quite tedious going along recutting the lettering, chiseling the edges, setting the gold, then polishing flush. My hat goes off to anyone that does this. It's a great look but very time consuming to say the least. I enjoy lettering and that's something that's a requisite for the job.

Barry. Thanks for taking such great photos and documenting your method.

Barry. Thanks for taking such great photos and documenting your method.

Mike Dubber

Elite Cafe Member

Sometimes you must first cut the letters from scratch, and then use the same methods described above to complete the inlays. Script letters are generally more difficult to inlay than block, but I use the very same methods to create the voids and anchor the gold.

algym

Elite Cafe Member

Gracias Barry por aportarnos esta información, es muy valiosa. Muchos de nosotros no tenemos la posibilidad de capacitarnos con grandes maestros como usted y este tema es maravilloso...

Saludos

Luis

Saludos

Luis

JMiller

Elite Cafe Member

Thanks Barry, Mike & Bert... lettering doesn't usually get too much attention, especially inlay. Thank you for the WIP.

davidshe

Elite Cafe Member

So helpful to see how you pros do this step by step. Thank you so much Barry, Bert and Mike!

Barry Lee Hands

~ Elite 1000 Member ~

My flat chisel, about .008 inches wide:

Cutting with the flat:

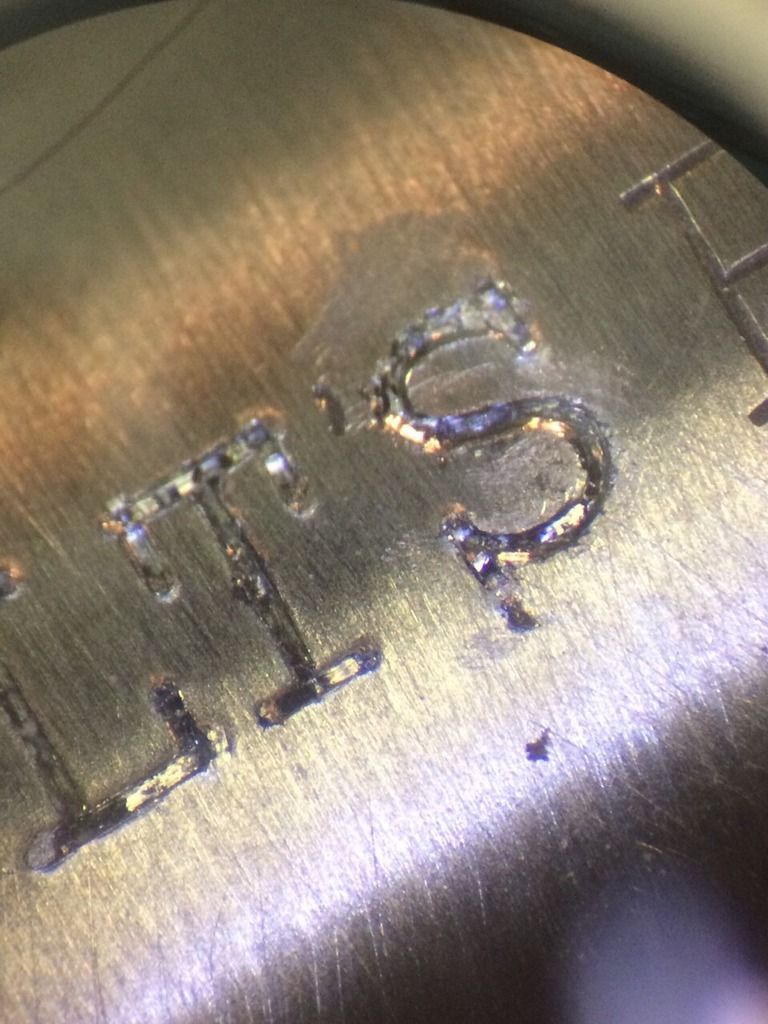

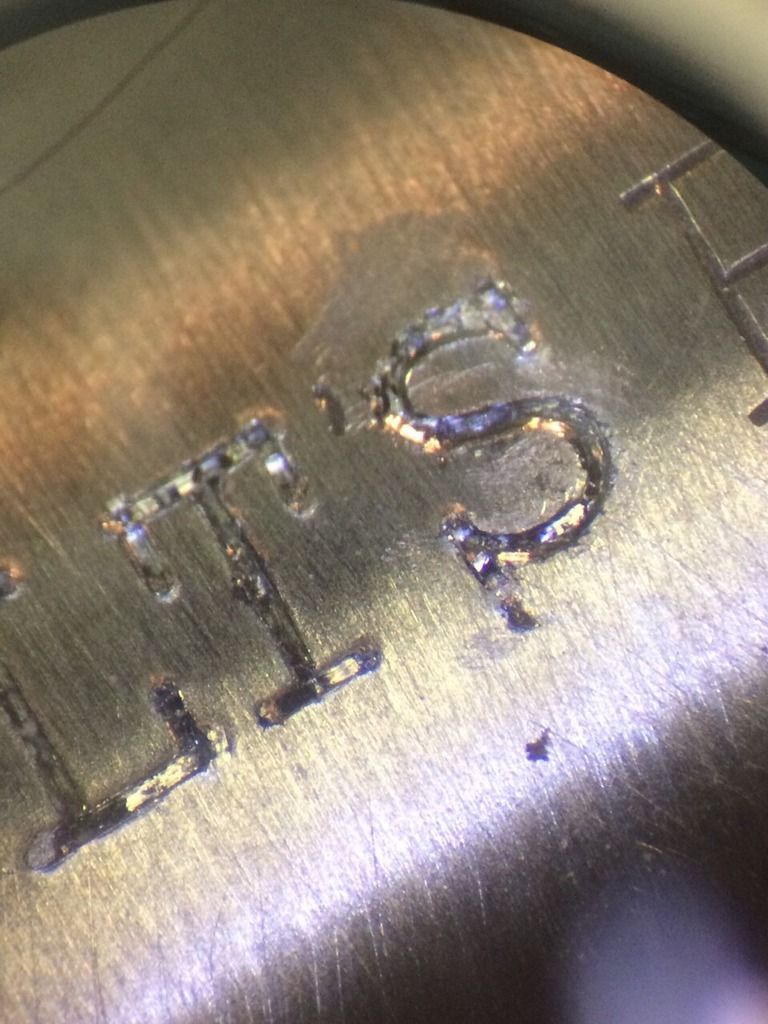

Curvy parts are trickiest, because outside edge gets ragged because of heel drag:

So, we punch it down with a flat:

Then I smooth it up with a scribe:

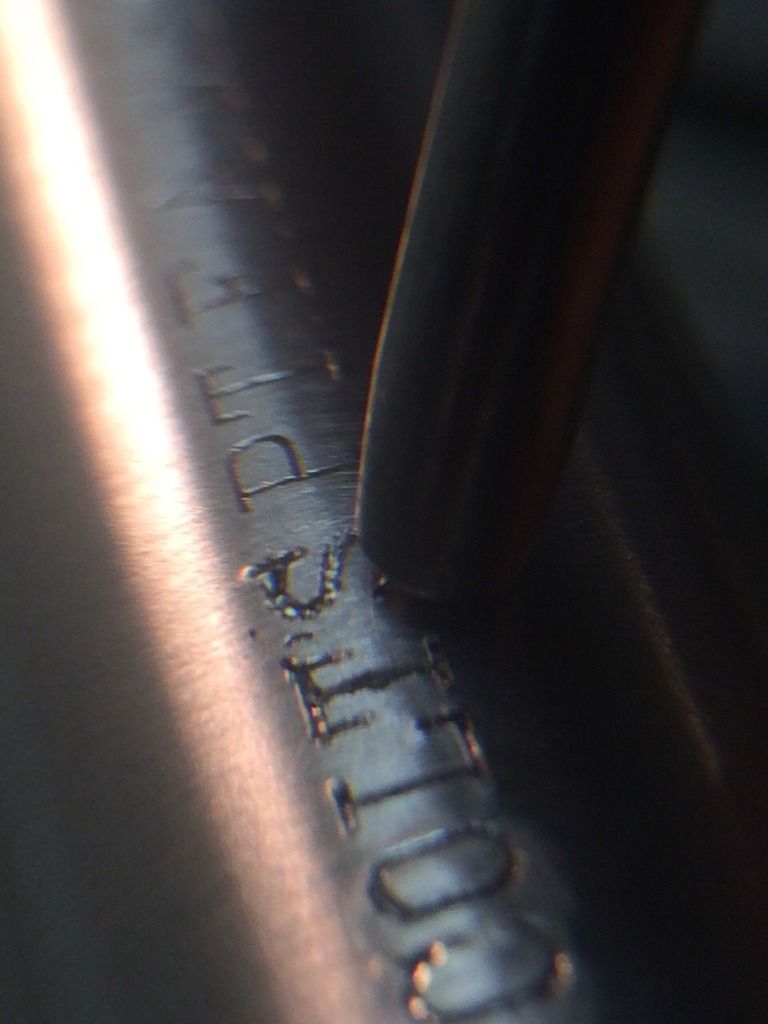

now it ready for the wire:

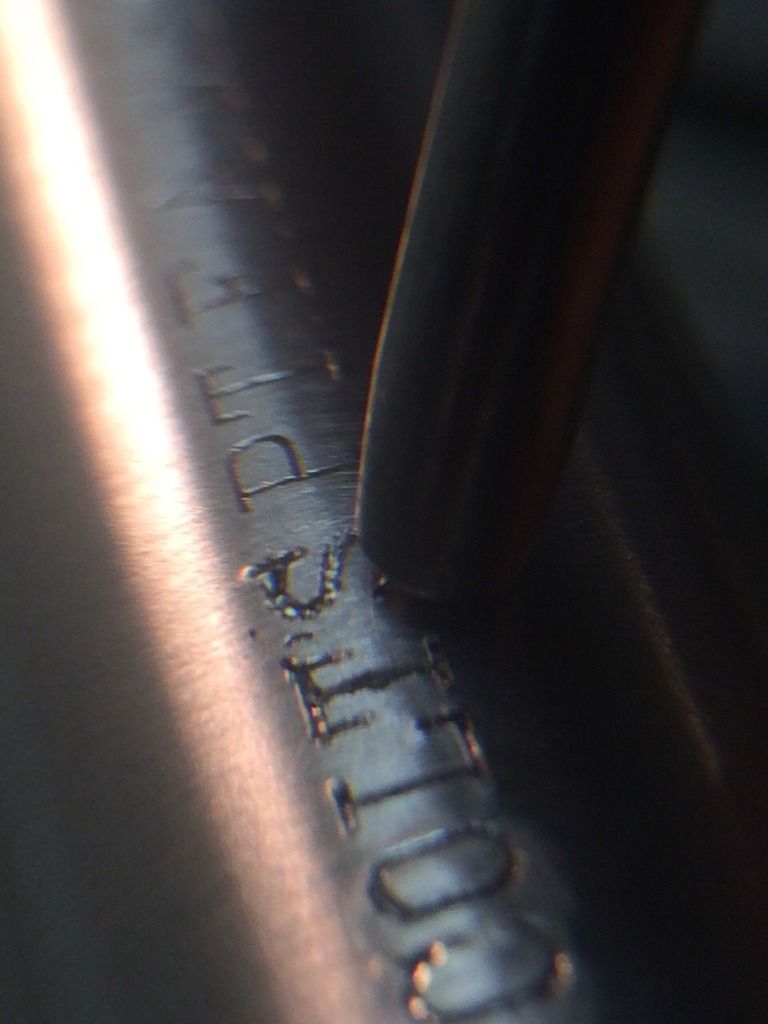

Finished lettering before final polish:

Yes, good stuff all around.

This is where I go next:

Cutting with the flat:

Curvy parts are trickiest, because outside edge gets ragged because of heel drag:

So, we punch it down with a flat:

Then I smooth it up with a scribe:

now it ready for the wire:

Finished lettering before final polish:

So helpful to see how you pros do this step by step. Thank you so much Barry, Bert and Mike!

Yes, good stuff all around.

This is where I go next:

Last edited:

Barry Lee Hands

~ Elite 1000 Member ~

Gracias Barry por aportarnos esta información, es muy valiosa. Muchos de nosotros no tenemos la posibilidad de capacitarnos con grandes maestros como usted y este tema es maravilloso...

Saludos

Luis

Luis-

De nada.

Adder

Elite Cafe Member

Great tutorial. It is so interesting to see how it actually shall be done.

Love it, and thank you all very much.

Jørn-Ove

Love it, and thank you all very much.

Jørn-Ove

Barry Lee Hands

~ Elite 1000 Member ~

Barry Lee Hands

~ Elite 1000 Member ~

Barry, is the barrel fixture you're using hand made or available for purchase, and if available, from whom?

Bill

Hi Bill,

I made it myself, many years ago.

It's inspired by the old Hurst/Rowles fixture, but aluminum and lighter.

Boomhower

Elite Cafe Member

Awesome work. Thank you for posting this for us. Inlay work is part of what has got me into engraving. I am just starting so I am a ways from giving it a try lol but your photos have helped my brain figure it out just got to train my hand now lol

Barry Lee Hands

~ Elite 1000 Member ~

thanks Boom, and you are very welcome.

Thanks Barry. Ken showed me his years ago before I really knew what was going on with it and suggested I get one from Carroll Rolles which I didn't do.....my bad. Gotta get one or make my own now as I'm tired of fighting barrels.

Bill

Bill

Last edited:

BrianPowley

~ Elite 1000 Member ~

Great looking work, el Presidente!