James Roettger

Elite Cafe Member

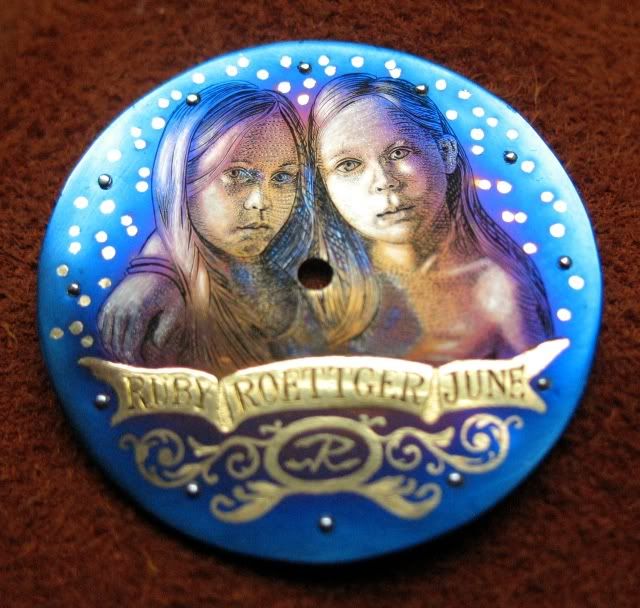

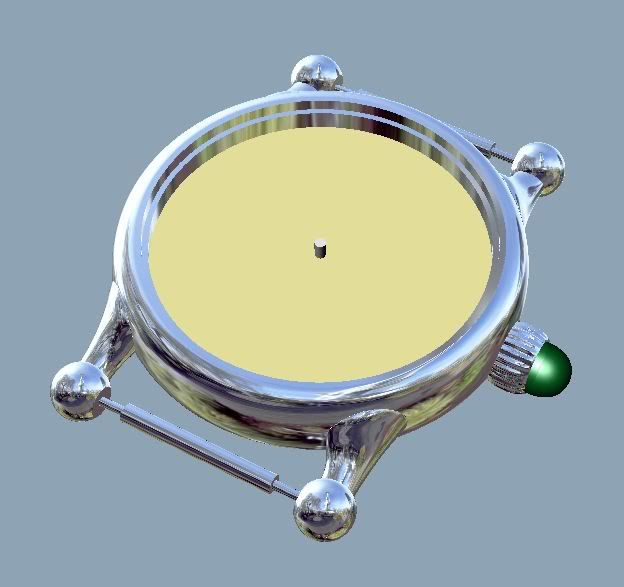

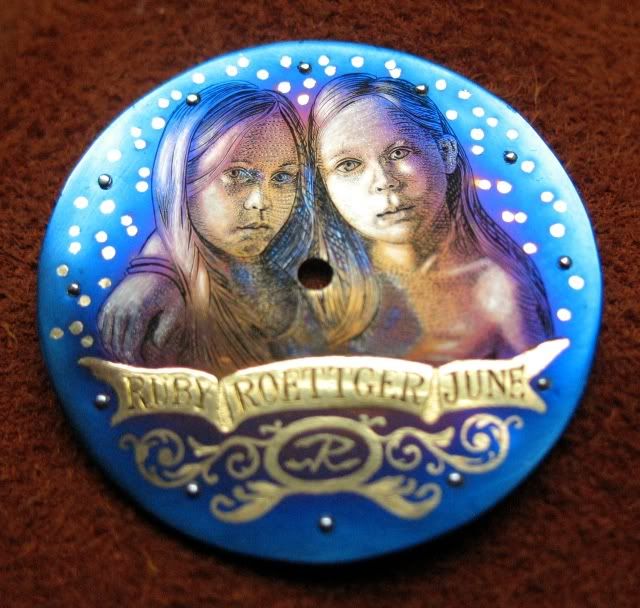

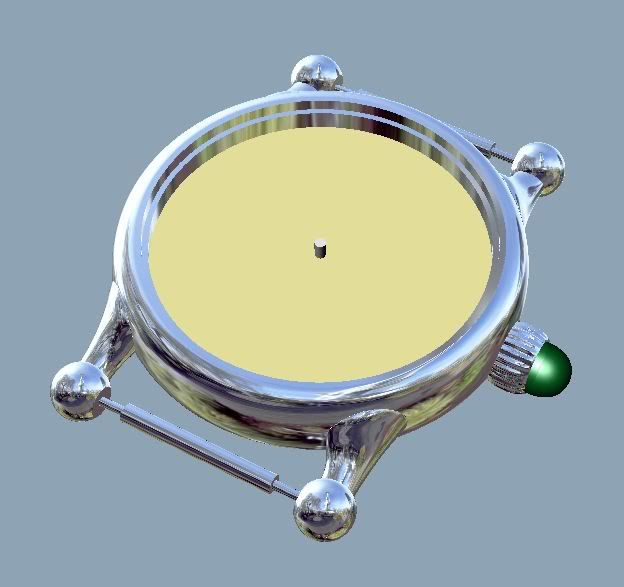

I started this watch 3 years ago and just finished it today. I experimented with several new techniques here including anodizing titanium, swapping out wheels in a watch movement to extend through an extra thick dial, more advanced bulino with gold inlay and applying my new CAD skill. The photos include several of the dial as well as the anodizer I built from scratch. In one photo is an electrified paintbrush used to detail the color burn. I learned that titanium cannot be anodized if any other metals are with it in the bath. Because this piece was inlayed with gold along with platinum buttons for the hour dots, the titanium resisted the electric current completely during anodization. The gold and platinum in essence became "sacrificial anodes". Because titanium has a lower electrical conductivity than gold it actually sided with the negative charge of the bath and all the positive current went into the gold and platinum. In experiments I learned that the titanium can easily be masked off with nail polish to create different color zones. One can conceivably color different areas at will as long as no gold is present. I ended up coloring this piece with a torch while it was spinning, creating the blue to purple to yellow color transition seen. I then was able to detail anodize the portraits using an electrified paint brush because the faces don't have gold on them and the current was isolated to very small areas by the brush. The dark blue near the center was added as well as some shading about the figures. I used no ink here as it just muddied the bright color. The case I designed in CAD and fitted the watch with an ETA manual wind movement which can be retrofitted with different wheels for thicker dials. The hands here are not the final hands. Twice the hands I ordered came in the wrong size so these hands will be swapped out later with more appropriate ones. This is a 30.5mm dial.1

WOW that is amazing work, James!! :clapping: My congratulations & thanks a lot for your explanation of the used techniques!

WOW that is amazing work, James!! :clapping: My congratulations & thanks a lot for your explanation of the used techniques! Paulie

Paulie